As you can see at this point track-laying had already started, as we'd realised it would be easier to lay the curve through the backscene and the point control wires before the backscene was in place. The curve is pretty tight, so the rails were slid out of the sleepers and pre-bent between fingers, before re-threading the sleepers back on. Track is glued down with PVA, held with a few track pins pushed into the foam-core until the glue has dried.

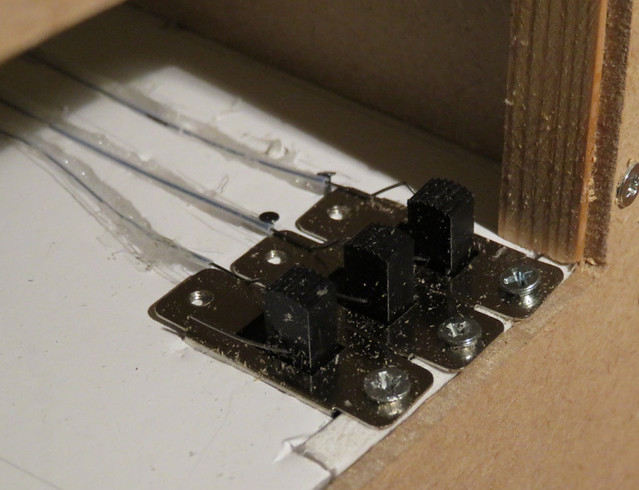

Point operation is by wire-in-tube, which was laid into a groove cut into the top of the foam-core board and held with hot glue. We've used the simple but effective trick of connecting the wire to a slide switch, which deals with frog polarity.

No comments:

Post a Comment