My usual preference is embossed plastic sheets, especially Slater's, as they are easy to work with, give a good relief, and can be painted to suit. However I haven't found a block-work wall sheet in 7mm scale. The Slater's 4mm paving is the closest match, although the "blocks" have the wrong aspect ratio really (not quite sure of the size either).

(Image taken from http://www.gaugemaster.com)

Scalescenes do a downloadable print-yourself "brickpaper"of concrete block walling, which seems to have the right colours and appearance. It's a long time since I have used brickpapers and I worry about them being damaged by scenic work etc., and perhaps most about their lack of texture and relief - especially in 7mm scale. Representing different types of block and construction would be tricky too. On the other hand it would save a lot of time.

(Image from http://scalescenes.com/products/TX39-Block-Wall)

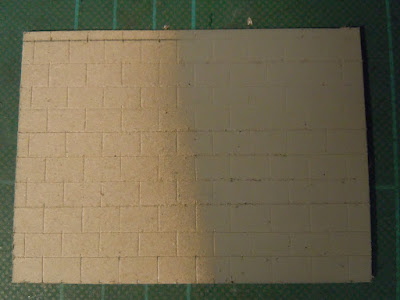

I have also been experimenting with home-made methods. The first is scribing card, which I have tried various implements with. Although the card has a good texture the scribing is tedious, difficult to get precise, and the scribed line is "fluffy". Below is a sample, the right side has been sprayed with grey primer.

I have also been experimenting with home-made methods. The first is scribing card, which I have tried various implements with. Although the card has a good texture the scribing is tedious, difficult to get precise, and the scribed line is "fluffy". Below is a sample, the right side has been sprayed with grey primer.

I've also experimented with expanded polystyrene foam, in this case pizza bases. I've seen this used to good effect before, and indeed the results are encouraging. Scribing is still tedious but seems to come out much better, the texture is good too. The bottom piece has been primed, amazingly the aerosol didn't dissolve the foam. However I am not sure the blocks are regular and sharp enough to be concrete, the courses too rounded and corners lacking definition. This would be great for stonework, but for concrete I'm still unsure...

5 comments:

Have you considered scribing plasticard with an Olfa cutter? Nice neat joins.

The piza stuff looks OK to me though. Breeze blocks have very slightly rounded corners and when weathered, do look less than tidy.

Thanks for the tips Phil. I don't have an Olfa cutter, I'll look out for one.

The photos from the site (those I took last week and those in the book) show very flat faced, sharp-cornered blocks, which I don't think the polystyrene scribing represents well, though it would be fantastic for stonework!

I used the Scalescenes printed breeze blocks for the interior of my Clay Dries and they were pretty realistic, but fragile if I hadn't sprayed them with matt varnish. But for the exterior, I used embossed plastic blocks, grouted with Das...it was surprisingly effective. That would also get rid of the rounded appearance, as most walls with breeze blocks display fairly arbitratry mortaring at the best!!

Experimentation has shown the work laser printer gives a more durable (water proof) print than my bubblejet. But a matt varnish is definitely a good idea.

I'd go for plastic sheet if I'd found any in O scale!

Sorry! I should have said hand-scribing plastic...lazy writing :-(

Post a Comment