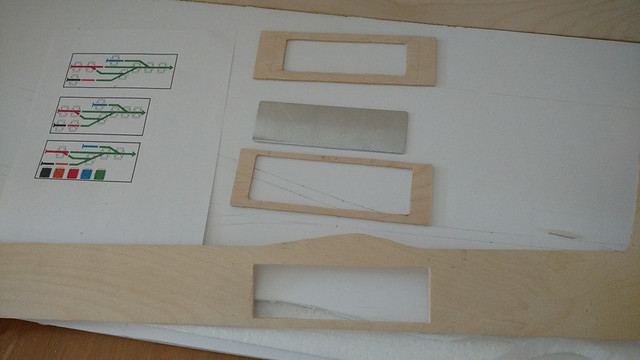

Here's my piece of aluminium, with some trial printouts of the panel layout. These aren't yet final, but show it will all fit. The fascia (bottom) has had a suitable sized hole cut out, with two other layers cut too, one to the size of the panel, and one a little smaller.

The two layers are glued behind the fascia creating a 6mm deep recess which the panel just fits, and a support which it will eventually be screwed to. These two layers also reinforce the thin ply edges so this is not a weak point. Meanwhile, the foam-core board is cut away with a knife to make space.

Fitting it together, you can see how the foam-core structure and the timber reinforcement conspire to make access from the rear so tricky. I've also added a socket for the power connections at the same time.

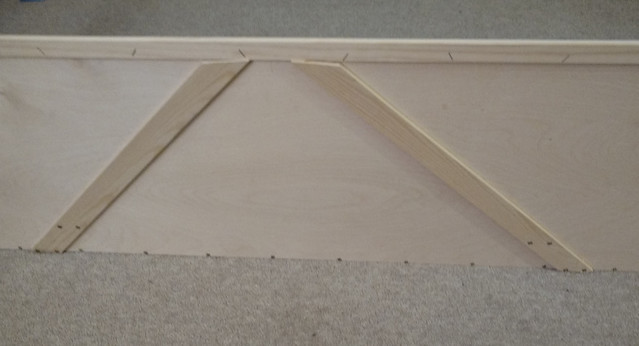

All fitted together. I need to drill the panel for the holding screws, when I drill it for the switches too. I've also cut and fitted the "wings" that frame the sides of the scene, and hide the untidy bits like split hinges and back-scene framing.

Talking of the back-scene, I've used some offcuts of the thin timber strip to brace it. These are screwed to the lower reinforcement, glued to the ply back-scene, and stapled through from the front. The ply back-scene is much stiffer now, with no tendency to bow.

So there we have it, one tidy looking, solid, yet surprisingly lightweight base-board. I do need to add a lighing beam - when I've decided what lighting to use - but for now I can proceed to track-laying!

2 comments:

If it takes one man two weeks to build one baseboard, how long does it take eight men to build two baseboards?

About two years... ;)

Post a Comment