With the plan decided, final adjustments to the positioning of the points was made - with a layout this size a few mm either way can make a difference to how the layout works.

Michael Campbell's blog about his model railways. Building model railway layouts in 009 (OO9) scale

Monday, 19 May 2025

Rail 200 challenge - getting started

Monday, 5 May 2025

Rail 200 challenge

To mark 200 years of railways, Peco have launched a micro layout/diorama competition. For £30 posted you get the baseboard kit, a length of track, and it comes in a large cardboard box that can be used to store/ship the finished layout. It seems these have proved popular as the first batch of 200 sold out within days, and several more batches have been release (probably as fast as the supplier can make them!). Now, I didn't order one straight away as I don't really need another layout, but I do enjoy a challenge and it seemed a shame not to take part...

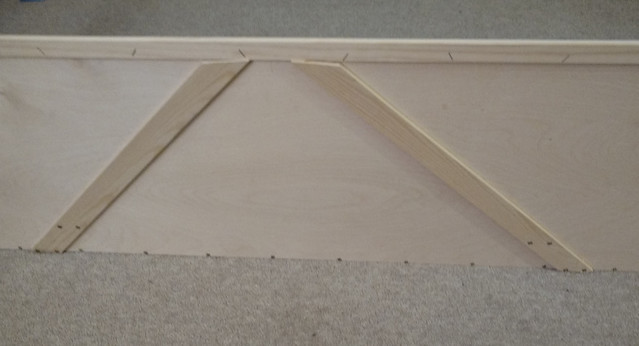

...so I drilled a pilot hole and put a countersunk screw to hold the end tight to the deck. I also put one into each side beam (bottom left and bottom right) in case pulling in the top allowed the bottom to move out, and for good measure three screws the opposite end to match. These may not be necessary, but assembly including the screws was no more than 30 minutes.

Now I just need to decide what to build. I've doodled a few plans, of which more later, but here's some of the inspiration that may be used...

Saturday, 30 September 2023

Rebuilding the "ultimate" fiddle yard

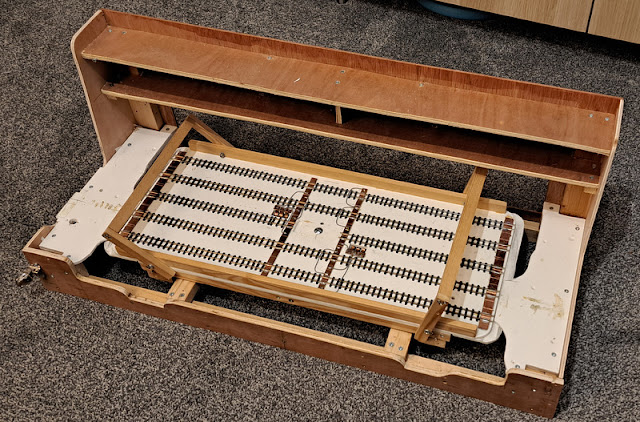

Despite the back-to-front build I managed to get the fiddle yard constructed to fit to the Hexworthy baseboard, with a deck that slides to align tracks then slides right out to allow the deck to rotate. The rotating deck with end-gates that also lock the rotating deck to the sliding deck is pretty much unchanged, but most of the rest of what is seen here has been modified or reconstructed. Yes I do seem to over-complicate things! Next up will be the latching and electrical system.

Sunday, 9 October 2022

A new fiddle yard for Hexworthy

Hexworthy was designed to use the same exhibition-friendly fiddle yard I'd made for Awngate, but that is large and not pretty, so for home use a compact fold-away fiddle yard was built with a simple 3-road sector plate. It's seen here before the boards were painted grey. The frame attached to the layout with split hinges front and rear for a rigid joint, and the board rotated around the vertically-mounted flat hinges to stow inverted over the layout.

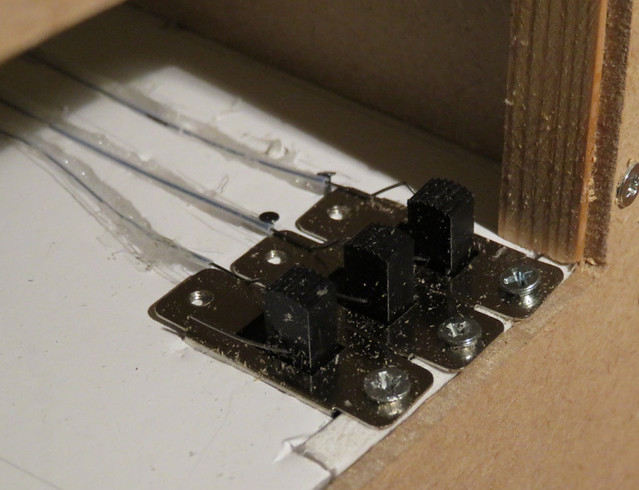

The new arrangement is much easier to connect and release, especially when reaching behind the layout on the shelf unit. The connection is not as rigid as the split hinge, which allowed one end of the layout to be lifted without any bend at the join, but having got the catches as tight as I could it seems good enough and the dowels make for just as good alignment.

Now I need to fit the sector plate and tracks, although it might be a couple of weeks. Next weekend Loctern Quay will be at Uckfield, which looks to be an excellent show as always. Do say hello if you're there.

Wednesday, 11 September 2019

Back-scene boards, legs and lighting rig

However as usual I couldn't help but complicate matters, because I also wanted to add lighting, and some short legs to lift the model above table height. I figured it would be nice if both legs and lighting rig were attached to the board, and hinged out for use...

The result works well enough, but it was rather fiddly to achieve! The lighting rig hinges up for more height, and will hopefully have LED strips behind it that shine down on to the layout, the angled pelmet should be useful for that. It is supported by flaps that hinge down and sit on top of and act as an extension of the side wings.

A close-up of the lighting rig supporting arm shows the hinge and the support piece. When folded down the lighting pelmet overhangs the front of the layout, hopefully it will be useful as a support for a protective cover in due course.

To locate the support I simply used a small piece of dowel as a peg, that sits in a hole at the top of the back-scene/wing support, it's enough to stop the lighting rig collapsing.

The legs are made in pairs and are bolted at the top to the back-scene supports, the bolts also act as pivots. These bolts will have washers and locking nuts, once the board is painted/ A third bolt is added to hold the legs in place, and will have a wing nut. Note the power socket is now in place too.

With the locking bolt removed the legs rotate 180 degrees and stow up the ends of the layout, the locking bolt is fitted back in another hole to hold them in place.

The photo below shows the layout from my eye height, it looks neat enough despite my dodgy woodwork, and takes seconds to set up and stow away. It should work well at exhibitions, which is just as well as it already has an invite...!

Now it all needs painting. And I need to get on with some buildings.

Sunday, 18 August 2019

Baseboard modules and track laying

I chose the board with the dropped front, which gives potential for a wharf or harbour. You can see the holes drilled for point operation, and the rectangular hole for an under-track magnet.

The other board has the sector-plate fiddle yard, and a number of laser-cut holes - some of which have no obvious purpose! The lower deck to support the sector plate is held by four bolts, but I've glued it in place so the bolts (which may get in the way) can be dispensed with. I've drilled another hole for point control, and a couple of curved slots under the sector plate - I'll cover this in another post.

I also cut down the sector plate, shortening it by an inch. This was necessary to fit the track arrangement. Before laying the track I stuck brown paper over all the holes, and under the points and where magnets will be installed I used a black Pro-Marker to ensure bare baseboard wouldn't show where ballast can't be applied.

Track-laying started with the three points and the short straight between them, as getting this arrangement in the correct place was critical. There are insulating rail joiners between the two right-hand points. Next was the reverse-curve into the fiddle yard, this was really tricky and the radius here is under 12", probably about 10", but I'm hoping that with smooth transitions it will run smoothly. This layout is only intended for small locos and 4-wheel wagons after all. Then the other tracks were added, using a 12" tracksetta for the curve, and finally insulating gaps cut with a saw disk in a mini-drill for isolating sections.

The track is stuck down with PVA glue, held with track pins (the chunky ones from Gaugemaster, that can be hammered without wilting!) although these are positioned between sleepers and next to the rail to hold any curvature - not through the sleepers - and are removed after the glue has set. The track is weighted with anything heavy while the glue dries, tins from the larder are useful!

The Peco 009 track for this little layout all came from my own hoard, the points were recovered from a previous layout but had never been ballasted and showed no signs of glue residue. After a clean in some warm water and Cif, and a polish of the rail head with a fibre-glass cleaner, they looked in good shape. The track is a mixture of left-over bits, including both crazy-track and the "mainline" type, although only the tracks on the sector plate had been used before.

Tuesday, 5 February 2019

Extending Slugworth

The board is made like the main board, with a deck and bracing of foam-core, and an outer skin of 3mm MDF, stuck together with PVA and hot glue. Small blocks of wood are used only in the corners.

A couple of blocks of wood were added to the end of the layout, which has had the temporary end-stops removed from the tracks.

The extension was given a coat of the same grey paint as the outside of the layout, then screwed to the blocks of wood. Note that the extension is cantilevered from the main board, and has a tapered underside, it also has a slight curve to the end to maximise space for the track.

Next the track was added. For the curve, the rail was removed from the sleepers and bent carefully in the fingers to approximately the required curve before being refitted. The sleeper web was cut under the outer rail so the sleepers don't limit the radius or twist causing gauge narrowing, the track is then glued down. A couple of copper-clad sleepers are soldered to the rail where an isolating break is required, to hold the rails, and then the rails cut in-place.

Wires were fed through from the main board, and the new track tested. Slugworth is now a continuous run!

Wednesday, 11 July 2018

A board becomes a layout

As you can see at this point track-laying had already started, as we'd realised it would be easier to lay the curve through the backscene and the point control wires before the backscene was in place. The curve is pretty tight, so the rails were slid out of the sleepers and pre-bent between fingers, before re-threading the sleepers back on. Track is glued down with PVA, held with a few track pins pushed into the foam-core until the glue has dried.

Point operation is by wire-in-tube, which was laid into a groove cut into the top of the foam-core board and held with hot glue. We've used the simple but effective trick of connecting the wire to a slide switch, which deals with frog polarity.

Monday, 9 July 2018

Another distraction

Having helped me with exhibiting my layouts for the last few years, my son has been saying for a while that he wanted to build his own 009 layout that could be taken to exhibitions, a small layout like the EXPO challenges. Then he found out about the Dave Brewer challenge for this year's EXPO-NG show, which is to build a layout 50cm by 35cm, and decided that he was going to build a layout to enter.

Of course what that means is that he is going to get me to help him build the layout, including advice and doing anything he deems too tricky, so the result will be a bit of a joint effort. However that does leave us a challenge in simply making the time to work on it - there's not a lot that Joshua could do without supervision, and I'm not doing anything without him.

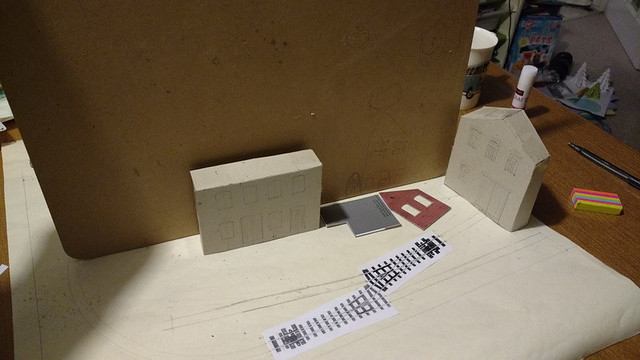

We've been working on it for a few months now, but I'll rewind the story to the planning stage. This was mostly done full-size on a piece of lining paper, with paper point templates, and some mock-up buildings made from cereal packets. We tried out a few ideas, and even has some input from Mum, before he settled on the design he wanted.

The baseboard was made from foam-core board, which is easy to cut with a knife, even for an 11 year old. The parts are stuck together with a hot glue gun. The top is double thickness, laminated with PVA glue, and blocks of wood were set into the corners ready to screw side panels to later.

More soon...

Saturday, 15 April 2017

Baseboard Finishing Touches

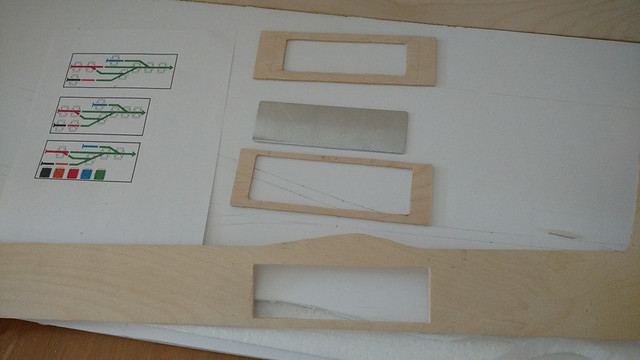

Here's my piece of aluminium, with some trial printouts of the panel layout. These aren't yet final, but show it will all fit. The fascia (bottom) has had a suitable sized hole cut out, with two other layers cut too, one to the size of the panel, and one a little smaller.

The two layers are glued behind the fascia creating a 6mm deep recess which the panel just fits, and a support which it will eventually be screwed to. These two layers also reinforce the thin ply edges so this is not a weak point. Meanwhile, the foam-core board is cut away with a knife to make space.

Fitting it together, you can see how the foam-core structure and the timber reinforcement conspire to make access from the rear so tricky. I've also added a socket for the power connections at the same time.

All fitted together. I need to drill the panel for the holding screws, when I drill it for the switches too. I've also cut and fitted the "wings" that frame the sides of the scene, and hide the untidy bits like split hinges and back-scene framing.

Talking of the back-scene, I've used some offcuts of the thin timber strip to brace it. These are screwed to the lower reinforcement, glued to the ply back-scene, and stapled through from the front. The ply back-scene is much stiffer now, with no tendency to bow.

So there we have it, one tidy looking, solid, yet surprisingly lightweight base-board. I do need to add a lighing beam - when I've decided what lighting to use - but for now I can proceed to track-laying!