For this one I used the supplied roof parts, although I trimmed a little off both the width and the depth to make it a better fit. I had fitted the chimneys to the walls rather than sticking them on the roof, so the roof was cut to fit around them.

The short rear part of the roof (being a low-relief model) is attached with off-cuts of card and foam-core, while barge-boards are cut from card (none being included in this kit) and fitted to the outside of the ends.

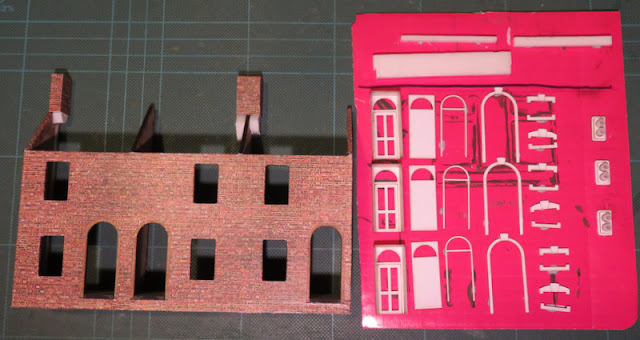

Now I omitted to take photos of the intervening steps, so here's the completed model after the details were painted and fitted.

A few notes on the details:

- The door openings were painted the same stone colour as the surroundings, and the window lintels and cills

- Doors, porches, and frames were painted separately. Curtains are coloured paper, and the inside of the building is painted black

- Inside the porches were floored with checker tiles and lined with ceramic tiles to waist height, using textures from the internet

- The roof was made from York Modelmaking slates, which were then painted picking out individual slates before being given a grey wash to harmonise and fill the gaps (I should have painted the roof base black first, but fortunately it isn't visible).

- The ridge is a strip of micro-strip, covered with a strip of newspaper margin coloured grey with a felt tip pen, to represent a lead ridge. The lead flashing around the chimneys is made in the same way

- The gutter is a strip of 40-thou black plasticard with the front lower corner rounded, simple but very effective. Down-pipes are 40 thou micro-rod with the brackets represented by small strips of plastic.

I'm pretty pleased with the result, which looks pretty good even in this cruel close-up photo.

Despite the distractions of Christmas and the general busy-ness of this month I've also been working on completing the other buildings, but I'll update on those in another post.