A while back I discovered that a simple Hornby "wall-wart" transformer could be used to power my layouts, a much neater and more compact solution than an open-frame transformer mounted in a home-made power box (see below). So I thought it worth getting another. This one is a Hornby C912 rather than the C990, it's rated 16V AC at 14VA which I make to be 875mA, so pretty much the same as the C990 which is rated 800 mA at 16V AC. Either type can be bought on ebay for less than £10.

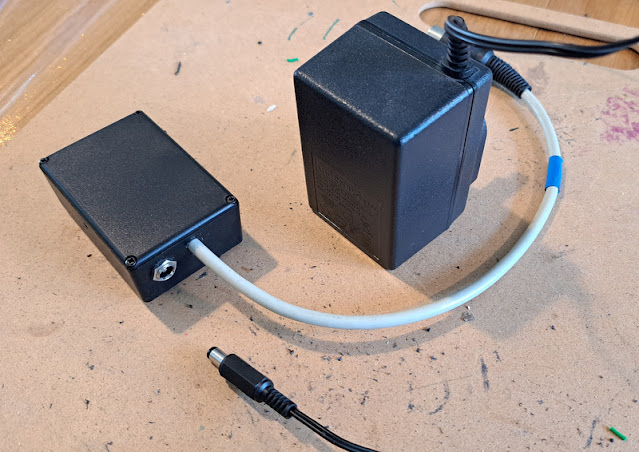

When I made the "micro" power pack I'd just hard-wired the power lead in, but it seemed neater to fit a plug and socket, and allow the transformer to be interchangable - not least as I like to have a spare at exhibitions. The transformer comes with a 2.5mm (inner) x 5.5mm (outer diameter) power connector, so I used a matching socket from Squires, and refitted a matching plug to the existing transformer.

Now the folllowing gets a bit involved! There is a risk with these connectors in that the LED layout lighting uses the same/similar type for 12V DC. In fact, the 12V transformers seem to use 2.1x5.5 plugs which strangely fit 2.5x5.5 sockets, very confusing. I think if I adopt 2.1x5.5 sockets for the lighting they will still work with the 12V DC lighting supplies, but while the AC supply 2.5x5.5 plug will fit the socket the inner contact will not be made. This all seems a bit odd! In any case, some clear labelling may be needed.

The convenience of the wall-wart transfromers has made me rethink my power box strategy. The original design provided not just 16V AC to both controller and layout, and so 12V DC from the controller, but also a high-frequency track cleaner, and a capacitor discharge unit (CDU) for points, all fed to the layout via a 6-pin DIN plug. The idea was that it kept all the complex and relatively expensive components together in a box that can power any of my layouts, rather than having to add them to each layout.

Now, I no longer use a high-frequency track cleaner, modern motors don't like them and anyway the use of graphite on the rails has made them redundant. I've also found that the points on a small layout can be driven via a simple CDU made of 3 components in a choc-block connector, as provided in the mini power box seen above. However, some layouts - such as Slugworth - use manual points control and don't even need the CDU, so the mini power box is now simply a junction box. Clearly, it can be eliminated altogether...

So Slugworth has been modified by the addition of a 16V AC input socket for the transformer. This is wired into the 6-pin DIN socket. Now a 5-pin DIN controller plug will fit a 6-pin DIN socket, and fortuitously when I first wired my power box leads I matched the controller 12V DC and 16V AC pins between the 5 and 6 pin connectors (although for the controller the 16V flows in, from the power box it flows out). So here the controller can plug into the 6-pin socket and both it and the auxilliary 16V AC supply (e.g. for lighting) are powered from the plug-in wall-wart transformer, with no external junction or power pack needed.

Of course, as the existing wiring is unchanged the power box can still be used with the controller plugged into that, and no separate transformer is plugged into the layout. This seems a bit complex but hopefully the diagram makes sense.

I did add a thermal trip to the 16V AC supply, I expect these sealed transformers have one built in but better safe than sorry. This trips at 1.6A which may be a bit high, but if there is a short it should trip.

This view underside of Slugworth shows the existing socket (left) with the controller plugged in, and on the right the new power socket for the 16V AC transformer wired to both the controller socket and to the lighting power circuitry. Of course this is how many people already wire up their layouts, but the approach I've used maintains "backward compatibility" for the existing power box to be used instead, or as a back-up.

This simple modification could be made to any of my smaller layouts to eliminate the need for a separate power box (and another lead), and just use a cheap wall-wart transformer. Layouts that need a CDU for point control could have the simple circuit added on-board too, although for now the micro power box used on Loctern Quay does that job.

No comments:

Post a Comment