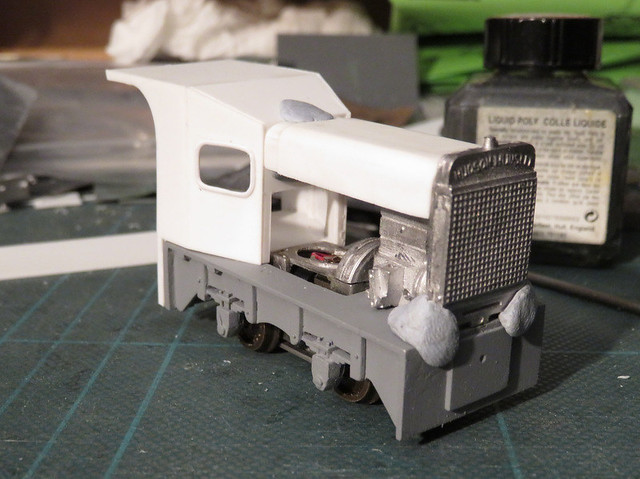

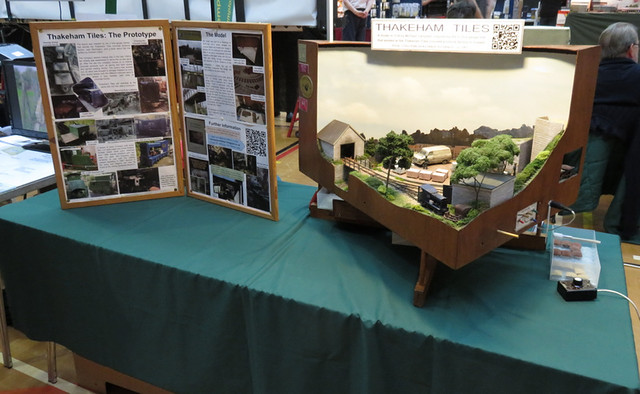

Another EXPO NG, and as usual, a great day. Thakeham ran without problems, which is always a relief, and received many nice comments. I'd been concerned my son wouldn't be up to helping out, as he'd been suffering a rotten cold, but fortunately he was sufficiently recovered to come, and again was a great help with operating the layout - which meant I got time to look around in breaks between operating. At least at EXPO operating never got too monotonous as there was often someone to talk to, so thanks to those readers who introduced themselves (which just proves there are readers too!).

The show had many great layouts - of which a few are shown below - but also some of the best trade support of any show, for narrow gauge interests. I did find time to pick up a few bits and bobs that will make their way into future posts I'm sure!

My son's favourite layout - and probably mine too - was L'Aubraie (7/8" scale, 45mm gauge) by Bernard Junk. It featured a working excavator to fill wagons, which were then tipped into a waiting lorry...

However it was the incredible detail that made the layout stand out, and that was done with a level of humour...

The Corn Mill (009) by Henk Wust, Derk Huisman, and John & Jane Jacobs, had impressive scenery.

Up The Line (O-16.5) by Kevin Hughes was a detailed and atmospheric depiction of the War Dept Light Railways of the Western Front in WW1.

P'tit Train se la Haute Somme (009) by the Association des Modelistes d'Amiens Longueau is a model of the line of that name in North-East France. Impressively presented, it was like a series of paintings, but the trains moved.

Grindley Brook Wharf (009) by Tim Ellis is already a favourite of mine, and deserving winner of the Reinier Hendriksen trophy for best freelance layout.

I could go on, but I'll overload this post. So do browse the 70 photos I've put in an album for more quality narrow-gauge inspiration! As for the Dave Brewer Challenge, well that was almost an exhibition in itself, so I'll come back to the entries in another post!