A little while back, I posted about

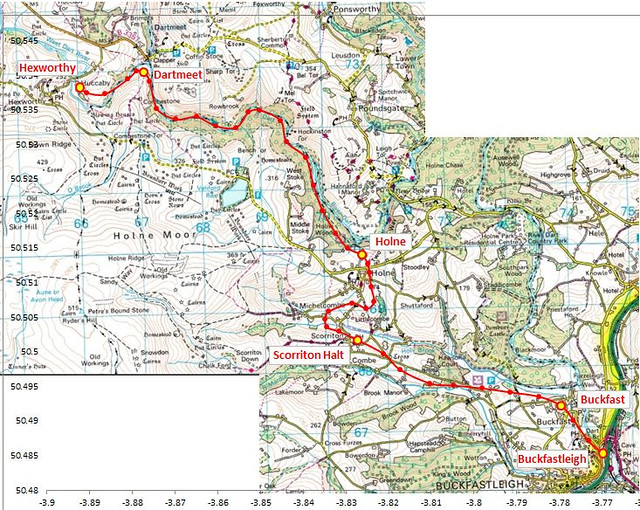

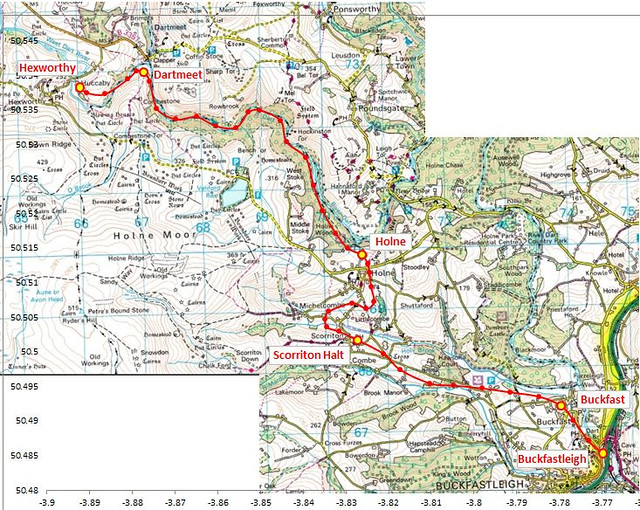

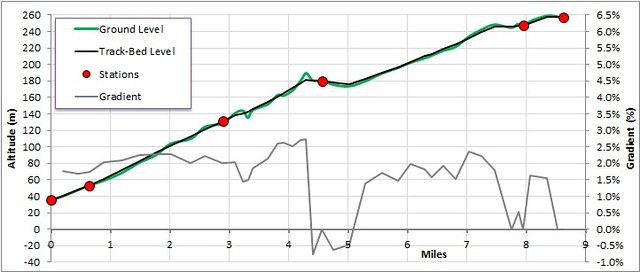

using map data from websites to plan imaginary railways. This was the route I plotted, for a narrow gauge railway running from Buckfastleigh to Hexworthy on Dartmoor.

There are a number of (long disused) tin mines and some granite workings around Hexworthy, some involved significant works, such as a mill leat that runs for miles across the moor following the contour lines, to power the mine machinery. So it's not unreasonable to suppose that wanting to increase their output in such a remote location, the mine owners got together to promote a railway. The terrain is pretty hard going and the budget was limited, so inspired by developments in North Wales, narrow gauge was chosen and the line opened in the early 1870's.

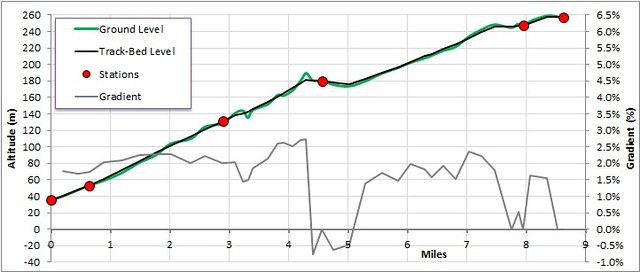

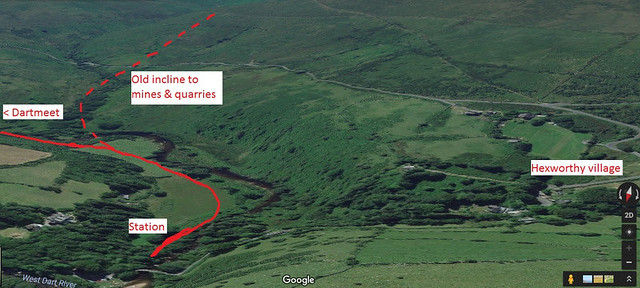

The railway starts in the yard of the South Devon Railway (later GWR) at Buckfastleigh which had arrived in 1872, where there were a couple of exchange sidings, and immediately starts climbing to reach Buckfast. This is where the sheds and workshops were located, there being more space. From then on the line climbs through open farmland to a halt near Scorriton, and curves over the Holne Brook valley with a small viaduct, before tackling the steepest climb to a deep cutting to reach Holne. This is the main passing station, and the point where the line re-enters the Dart valley. After a short downward stretch the rest of the route follows the valley side, climbing but getting closer to the river below, which is crossed near Dartmeet. A station here serves the main road, and became a popular tourist destination, but the final terminus is the quiet hamlet of Hexworthy, where a spur back across the river serves an incline to the various quarries, high on the moor to the south.

Now Tin was refined at the mines so unlike coal or slate, the outward traffic was low volume, high value. The remote location and the need for coal and stores for the mines, and to support and transport the workforce, made the railway necessary - rather like the Redlake Tramway built a few miles south, years later, where china clay was moved by pipeline. Anyway the point of this is that while gradients were considered steep, around 1 in 50 to 1 in 40 (2% to 2.5%) with a short section at 1 in 36 (2.75%), these were not unusual on NG lines and acceptable for the expected traffic, though in later years it limited train length as granite quarrying increased.

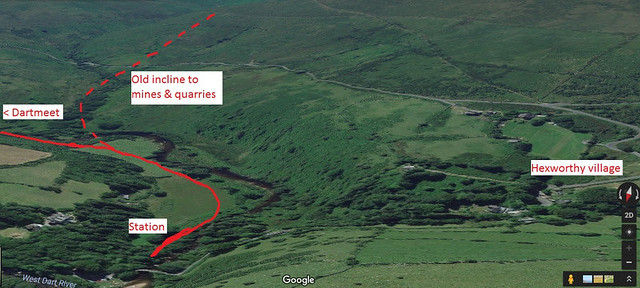

This is the setting of the station at Hexworthy, as seen by Google from the North West. The station lies along the river bank by the narrow stone bridge (bottom left), some way from the village of course! The mines and quarries are scattered along the top of the ridge to the South (right and top).

Now I plan to set my model in the present, or recent past, as a preserved line. This railway would have made a popular tourist line and although there would be no goods traffic, the works trains seen on preserved railways offer opportunities for interesting models and operation. I also like the juxtaposition of well-kept stations, locos, and coaches, with grotty maintenance wagons, workshops, stores, and even decaying stock awaiting restoration, that is often seen on "Heritage" lines. The fact that an imaginary preserved line is a great excuse to run whatever stock I please is a happy coincidence (honest...), but preservation is an era and setting that I, and many others who never knew the steam age, can relate to.

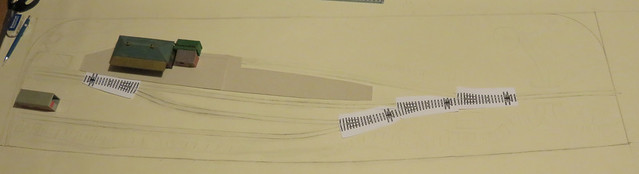

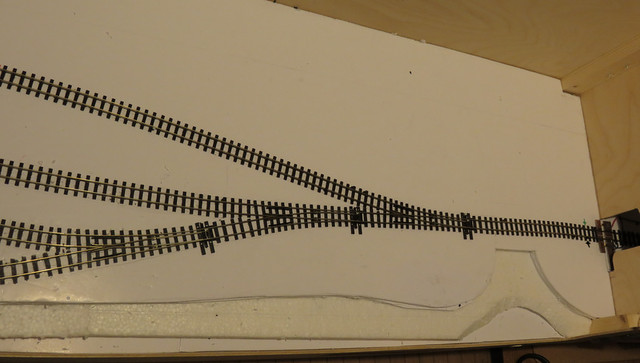

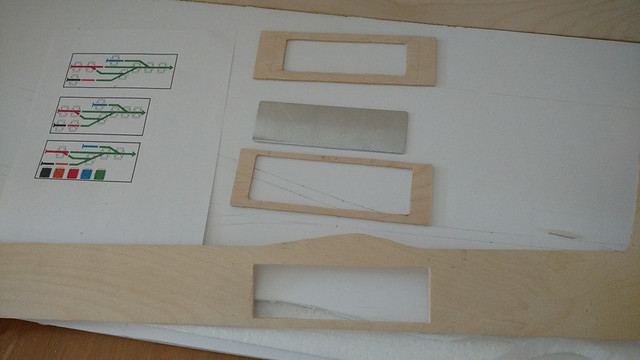

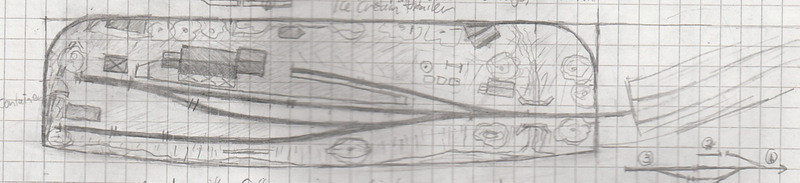

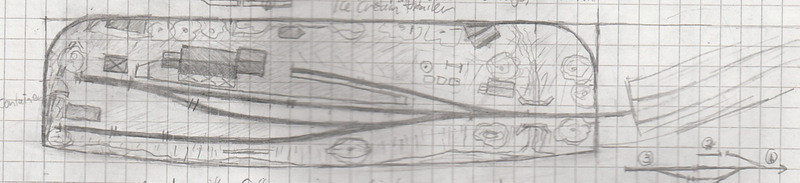

The idea for this layout has formed over the last couple of years, with dozens of plans sketched, but this is the final design. Earlier variants tried packing more in - with a workshop or engine shed, but I settled on "less is more" as preserved or not, I want to capture the open remote feel of the location. As well as a run-round loop there is a bay platform for spare coaches or "special" trains, this is a truncation of the old goods siding as the goods shed will be the station cafe. Along the river bank the quarry exchange siding is now used for maintenance trains, with an old shipping container or similar used as a store. Of course there will be a car-park, and maybe a playground, but it will be a quiet sleepy place between trains.

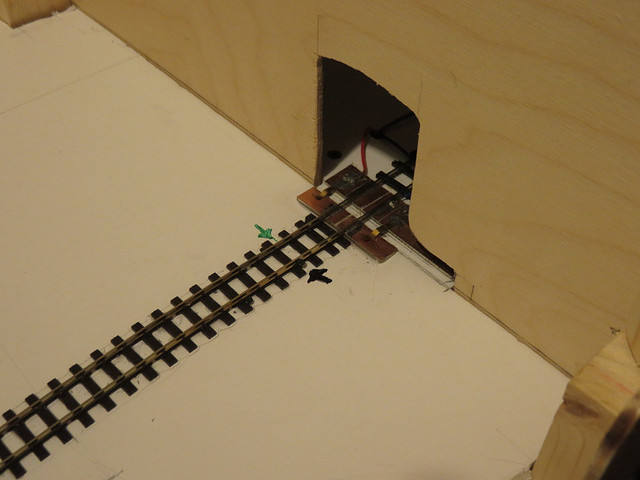

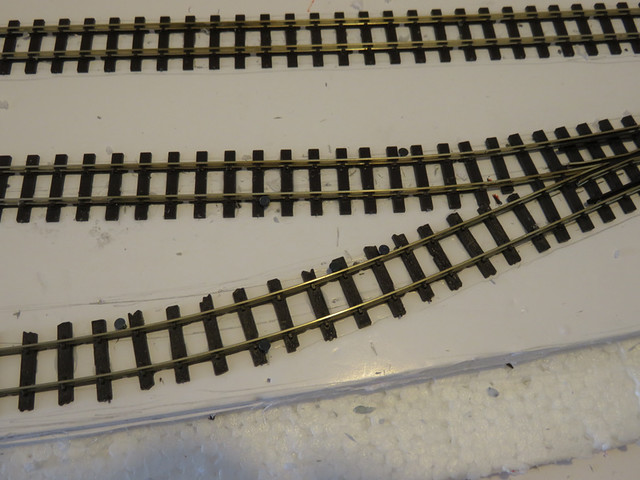

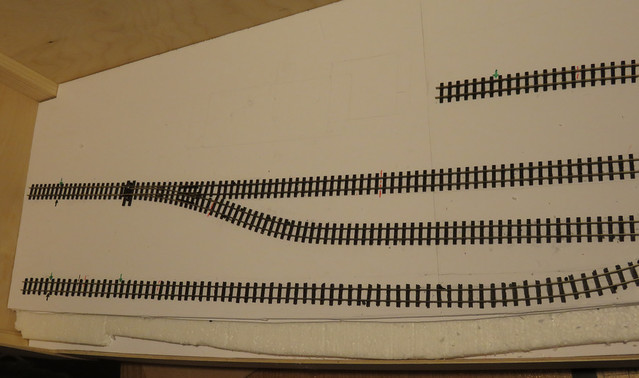

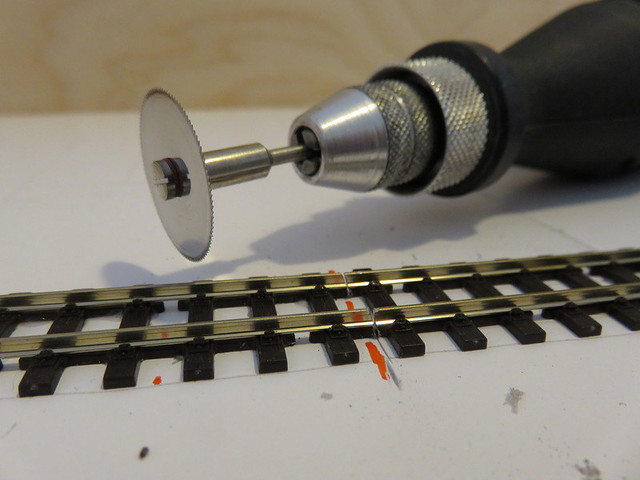

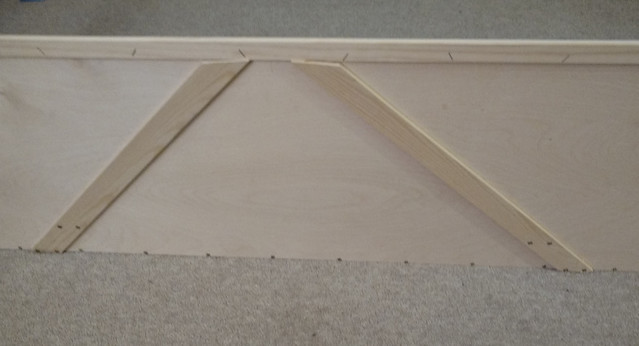

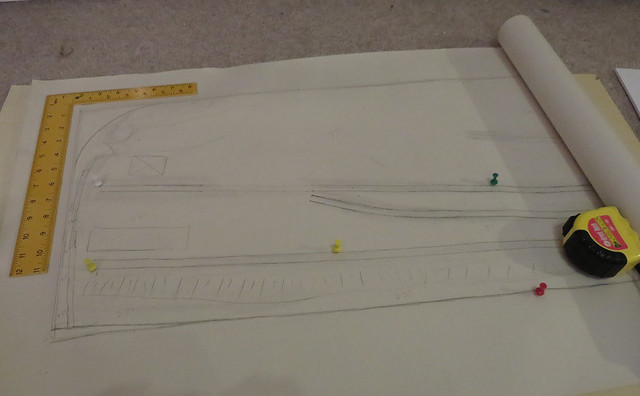

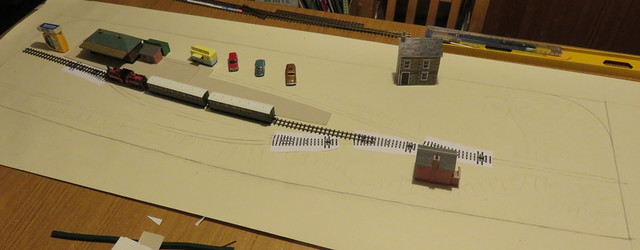

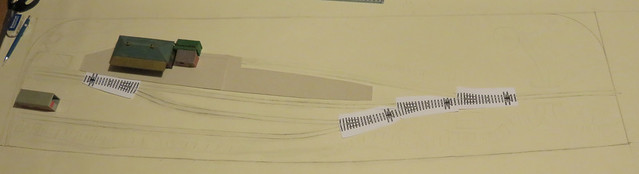

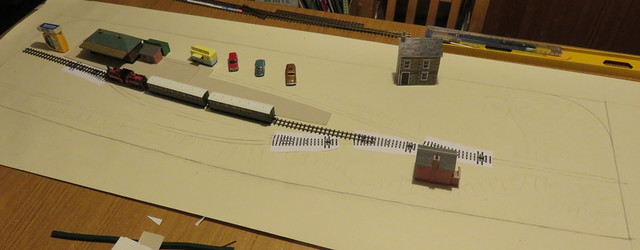

Sketches are useful but I always like to do a full-size plan before starting work. A roll of lining paper, some downloaded plans of PECO points, and a spare length of flexi-track are the essentials. A few buildings and vehicles are used to get scale - though any suitably sized object will do - and some stock placed to check clearances and perspective. It's very easy to rub out lines and move things about until things are just right - and on a small layout like this, half an inch either way can make a big difference to the way things look, and work!