The Gaugemaster/Faller woodland-style playground kit also included a see-saw. It does seem very long, but the style matches the other items in the set and I figured it could also be animated.

- The actuating rod is bent up from a paperclip, at the top it bends into a hole in the back of the see-saw. The hole is oversize to allow the arc movement of the hole relative to the rod.

- The short horizontal section at the top of the rod is partly as I found I needed to increase movement, and partly to allow some adjustment of see-saw position

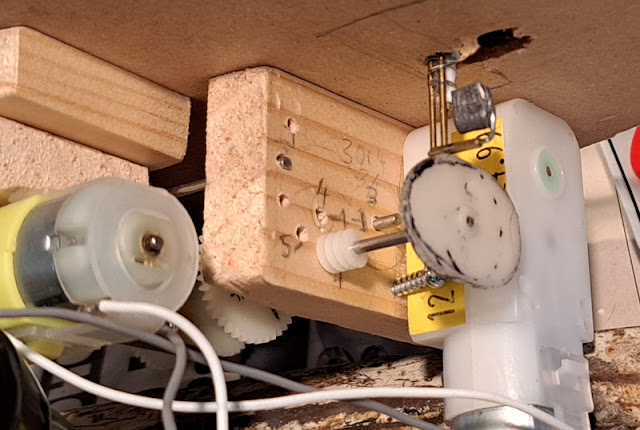

- The actuating rod passes through the base and then a short section of brass tube (it was quite a tight fit so a long section might bind), this is fitted into a longer plastic tube which is glued to the base. This join was later reinforced

- The rod then bends 90 degrees to run horizontally through parallel fixed rods, this prevents the actuating rod rotating. The fixed rods are secured to the plastic tube with wire wrapped around

- The actuating rod then bends again to pass over the cam, a length of brass tube acts as a roller, and is held in place by another bend in the rod

The cam is cut from a large gear, and raises the see-saw twice per revelation, with a deliberately irregular profile. This is driven from the same gear train that drives the swing but at the other end of the assembly seen in the last post, the cam rotates in about 5-6 seconds. The tail end of the actuating rod beyond the cam roller had a piece of lead clamped on to help ensure the see-saw dropped, I had considered a spring but this seems to work.

The video provides evidence that this Heath-Robinson arrangement actually seems to work!

No comments:

Post a Comment

Due to surprisingly high levels of Spam all comments will now need moderation. If you are advertising, don't bother, otherwise I must apologise if there is a delay in comments being visible, please don't let that put you off!