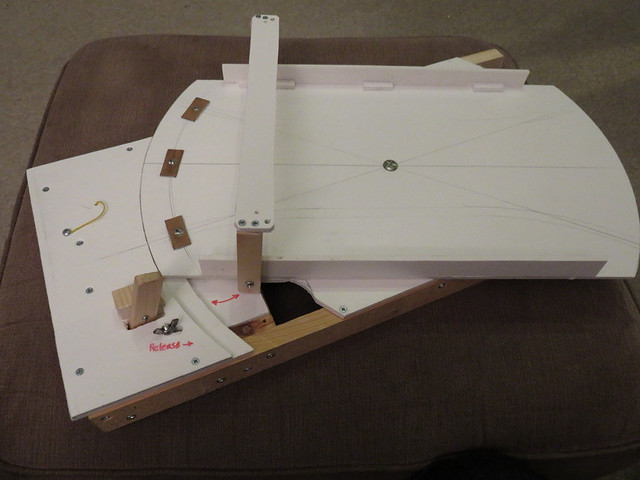

I saw an idea posted on a forum some time back that used a pivoted lever with a notch that engaged on metal edges aligned with and underneath the tracks, all that was needed was to depress the lever to release the engagement and move the deck until the next one engaged. The problem was it was bulky and required a lot of space below the deck, which the club layout design didn't allow. I felt the concept was sound though, and after some thought I came up with way that a similar idea could work in much less space, and be constructed with minimal need for accuracy and without special tools or skills.

Ideas are all well and good, but the only way to be sure it works in practice is to try it out. So I raided the garage for leftover bits of wood and PVC foam-board, and with literally no expense

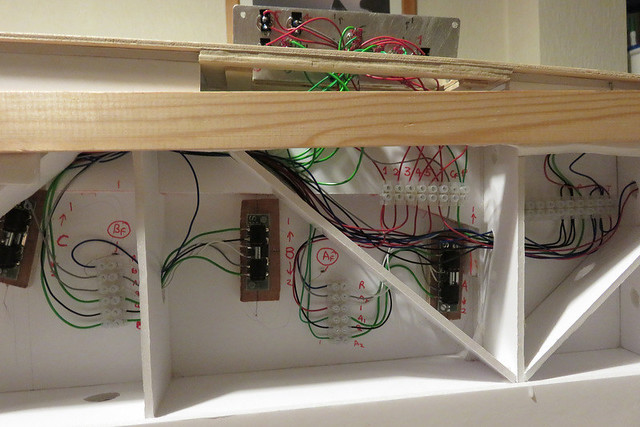

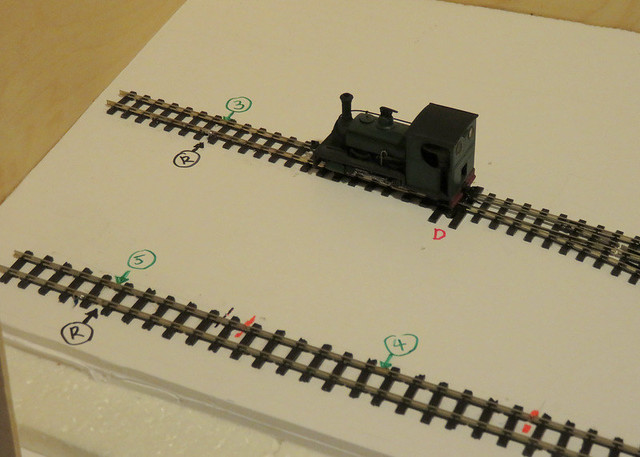

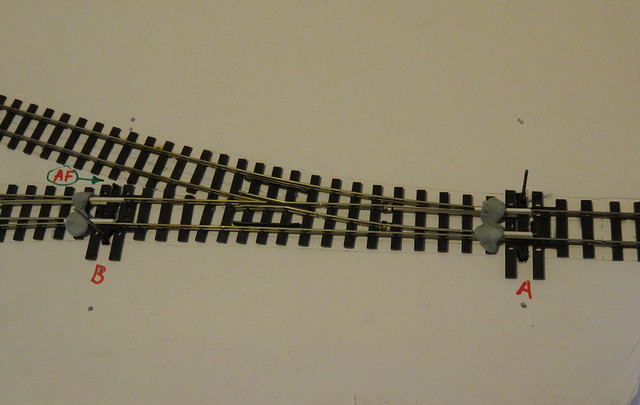

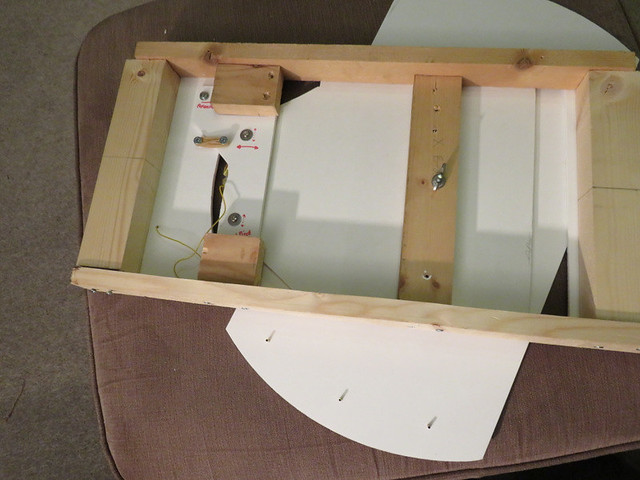

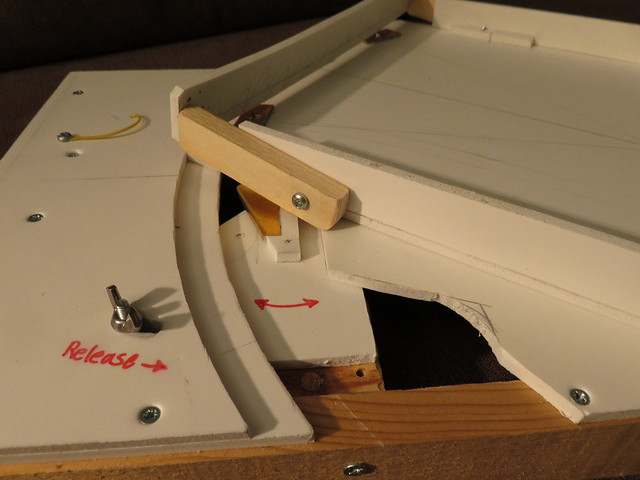

An over-view with the deck turned to the front track. On the deck are three pieces of PCB to which tracks would be attached, and through them the top of a brass tube/pin protrudes and is soldered. The handle we’ll come to later. To the left is the release mechanism – push the wooden lever to the left to unlock the deck to turn. The lever was an afterthought "improvement" - initially I just pushed the wing-nut (which could have been a nice wooden knob) to the right, but the lever is nicer to use. I guess that's the point of the mock-up!

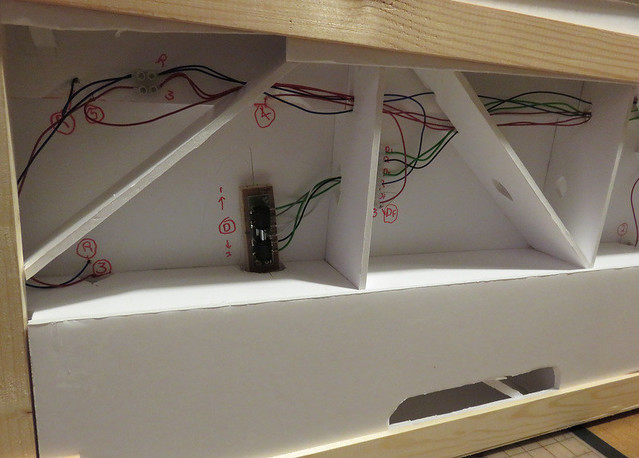

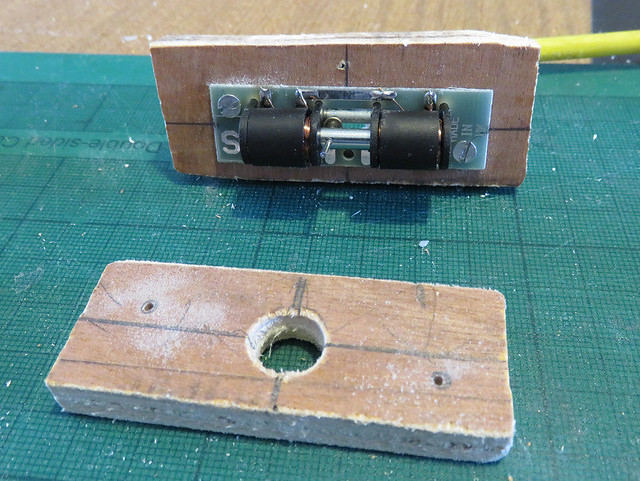

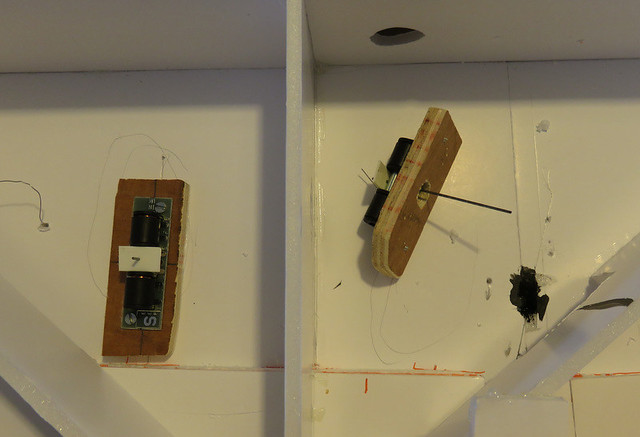

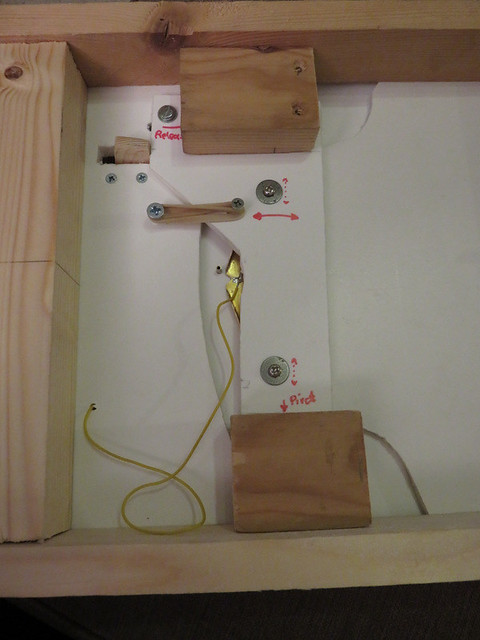

Under the deck you can see a brass “latch” (triangular with a notch at the top) attached to a pivoted lever, the free end of which is moved by the release knob (bolt) - and now the lever too (fitted after I took this photo). The support for the deck is shaped for a particular reason.

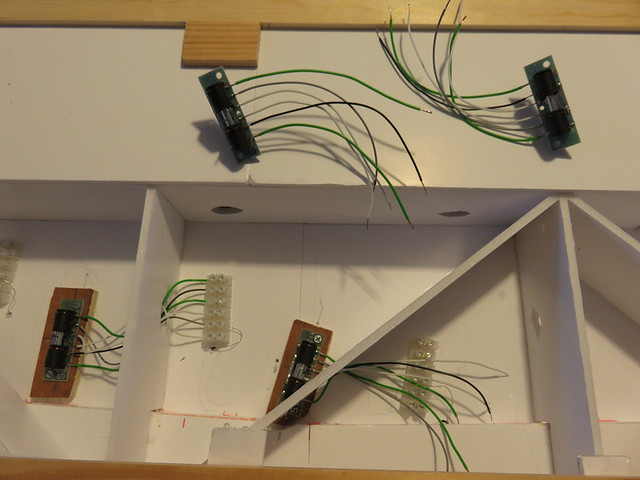

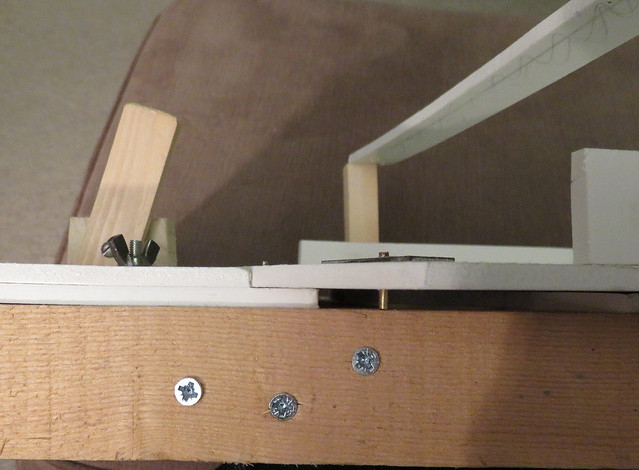

From underneath you can see the three location pins (brass tubes) protruding down through the deck, and the latch arm locking mechanism which pivots on the lower wooden block, the other end slides on the upper wooden block.

The latch arm close up, the bottom is the pivot, the top rotates as per the arrows, and is pushed by the bottom of the wooden lever. The high-tech tension device (rubber band in this mock-up, but a spring would be better!) pulls on back the latch arm. The bass latch can be seen with a wire from it, and against one of the slopes a location pin can be seen from the deck. As the deck is rotated this slides up the brass latch by pushing against the lever until it drops into the vee shaped notch, holding it securely and making electrical contact between the brass latch and the PCB above.

The location pins only protrude about 5 mm below the deck so clear the frame of the board – the foamboard is 5 mm thick - and at the top, protrude just far enough to be soldered to the PCB, and not foul locos passing over them. The rest of the mechanism is contained within the frame. This makes it reasonably straightforward to build this mechanism, and contain it within a conventional design and depth of baseboard.

Back to the handle. In the up position the tracks are clear, but when pushed right over the bottom of the handle uprights contact the supporting board below stopping excess movement. With the handle folded down the deck is free to rotate beyond the last track – i.e. can turn right around - as seen here.

Operation is simple: simply push the lever to disengage the pin and rotate the deck, once the lever is released the deck latches at the next track that it aligns with. As the brass pins are round, and the notch is vee shaped (with rounded entry), alignment is actually very precise - as the pin reliably self-centres in the vee. No effort is required by the user to achieve this, the deck is simply rotated until the pin clicks into place. Electrical contact is also made connecting the aligned PCB (i.e. table track) to the fixed track.

This system would be just as useful on a traverser or sector plate as a turn-table, and had I thought of it a couple of years back, I'd have used it on my "exhibition" fiddle yard for Awngate instead of the micro-switches. Some of the construction details could be improved from my quick mock-up, but overall I'm happy to say the concept works well.