The Worsley Works etch included the steps, so these would be simple I thought. However it quickly became apparent there was an error in the etch. As you can see the lower step is easily folded up, and the upper should slot onto the vertical - but the vertical plate narrows in the middle, so the upper step is too wide to fit. A check of the drawings and photos confirmed that the upper step should be narrower, in line with the vertical plate.

The only solution was to narrow the step. One "end" was cut off, the step cut short to match the narrow part of the vertical plate, and the locating tab shortened. Soldering the remaining tiny pieces together was rather fiddly, and I've got rather too much solder in there, but it worked and looks OK as long as you don't look too closely! The steps were then soldered to the underside of the body, behind the valance and in line with the cab entrance, and the plastic chassis support lower footplate was trimmed to clear.

Next the chimney, which is not very clear from the drawings and barely visible in any photos, so there is some guesswork. I found some brass tube, 2.3 mm diameter which seemed about right, though the hole in the roof needed filing out to accommodate it. To give it the impression of some kind of cap I made a loop of brass wire a tight fit around the tube, and applied plenty of solder. A little filing afterwards tidied it up and gave it a more probable shape. Since it is barely visible in photos it can only just have protruded through the roof, so I set it low to the roof and soldered it in place from behind. The nice thing about this is the chimney can be seen continuing through the cab.

The other roof feature which is also hard to make out from the drawings and pictures - though it protrudes enough to be noticeable - is the large plate or raised section. I found a piece of scrap brass the right width, and about 0.5mm thick, which was cut to length and curved to match the roof profile. Soldering it in place really tested the capability of my 25W Antex iron though!

The roof features and the steps really do start to give the model some character. I think that's all the soldering done now, so the body is being cleaned of flux, and I can add the final details to the chassis.

Michael Campbell's blog about his model railways. Building model railway layouts in 009 (OO9) scale

Pages

▼

Sunday, 25 January 2015

Thursday, 22 January 2015

Atkinson-Walker: More Soldering!

At the weekend I'd managed to pick up some square section brass for a more reasonable price than I'd been able to find it at the Bognor show. This is just what I'd been looking for to make the valance along the bottom of the body, though at 1.6mm square it is slightly over-size it looks fine. This was carefully cut to length and soldered on.

With that done I could solder the upper body in place, taking great care to get the pieces vertical and fitting together. The roof took ages to roll, being quite a thick piece of brass - perhaps I should get some rolling bars, but the fingers/pencil/carpet along with holding one edge in a vice got me there eventually. Those mini pegs came in useful again, soldering the roof in place was easier than I'd feared.

The brass section valences actually do lot to keep the body rigid, particularly through the doorways, which helped when adding the roof. They also help locate the under-frame (which needed a little filing to fit nicely) and hides the lower plastic footplate.

So I couldn't resist posing the assembled loco on the layout. It is certainly large - not surprisingly for a 3' gauge loco modified from a Standard Gauge design - however it isn't so far off some larger stock that I have. I'll have to compare it to a GVT tram loco, which are quite bulky.

There's still lots to do. The drawings show a large plate or raised area on the roof - it's barely visible in photos, as is the top of the chimney, so I'm not sure what these should look like or how to make them. They will add a lot to the model though. I also need to solder on the steps, then it's on to detailing like the water filler cap (again it's not visible in pictures), cab doors, and perhaps some basic interior detail. Brass etched buffer beams are provided, but to the profile of the Irish loco rather than the Redlake one, so I've started cutting some from plastic which will attach to the under-frame, and need to allow for couplings. The under-frame also needs sand-boxes and a few other details to finish.

With that done I could solder the upper body in place, taking great care to get the pieces vertical and fitting together. The roof took ages to roll, being quite a thick piece of brass - perhaps I should get some rolling bars, but the fingers/pencil/carpet along with holding one edge in a vice got me there eventually. Those mini pegs came in useful again, soldering the roof in place was easier than I'd feared.

The brass section valences actually do lot to keep the body rigid, particularly through the doorways, which helped when adding the roof. They also help locate the under-frame (which needed a little filing to fit nicely) and hides the lower plastic footplate.

So I couldn't resist posing the assembled loco on the layout. It is certainly large - not surprisingly for a 3' gauge loco modified from a Standard Gauge design - however it isn't so far off some larger stock that I have. I'll have to compare it to a GVT tram loco, which are quite bulky.

There's still lots to do. The drawings show a large plate or raised area on the roof - it's barely visible in photos, as is the top of the chimney, so I'm not sure what these should look like or how to make them. They will add a lot to the model though. I also need to solder on the steps, then it's on to detailing like the water filler cap (again it's not visible in pictures), cab doors, and perhaps some basic interior detail. Brass etched buffer beams are provided, but to the profile of the Irish loco rather than the Redlake one, so I've started cutting some from plastic which will attach to the under-frame, and need to allow for couplings. The under-frame also needs sand-boxes and a few other details to finish.

Wednesday, 21 January 2015

Atkinson-Walker: Making an Under-Frame

When I last posted about the Atkinson-Walker steam tractor I was pondering how to make the under-frame, which is not included in the Worsley Works "Scratch-aid" etch. I found some wagon under-frame mouldings in the bits box, I think from an W&L open wagon, and came up with a cunning plan.

I started by opening out a recess above the spring, which gave space to add a few extra leaves from micro-strip, a fiddly job but now they look like they could take the weight of a loco. The W-irons were cut away, and the axle-boxes rounded off slightly, as per an approximation of the drawing. The wagon frame was 1mm shorter than the wheelbase of the chassis so I cut and spliced in a piece of 40 thou, with a splice behind. The notches in the top are cut to clear lugs below the motor. In the photo below one frame is prepared, the other is just started on...

Then on to the outer frames. I'd remembered to take the book to work and photo-copy the drawing at 82%, bringing it to 4mm scale, which makes life easier. I did a few copies while I was at it, allowing me to cut out the frames and stick them to some 20 thou plasticard with a few drops of solvent. It is much easier than all that marking out, a few cuts and I had the basic shaped of the side-frames, there's a mark where the paper was stuck but I'll just stick that on the inside.

Micro-strip was added to the frames according to the drawings and pictures, and the wagon-frames with axle-boxes and springs positioned behind. A dummy lower foot-plate was also cut out, as seen above. The nearest side-frame shows the rear with the wagon sole-bar, this sits just below the motor with notches to clear the plastic motor support brackets on the chassis. The 20 thou frame sits against the side of the motor, which should give the right ride-height. It's now clear why it was useful to have the springs and axle-boxes from one piece of plastic - there is nothing to support them except from the frame above, strictly speaking there should be a gap above the springs too but the lack of that won't be visible!

Holes were then drilled through the plastic lower footplate and the brass footplate of the body for the bolts - I decided one at each end, off-set to allow for couplings to fit centrally. An M2 nut is soldered above the floor, by threading a Vaseline covered bolt with another nut from below and tightening. A little flux applied around the nut with some small pieces of solder, then apply the iron. In theory the Vaseline stops the bolt getting soldered too, and it did - but on the second one some solder got into the bolt thread between the nut and the brass sheet. I managed to unscrew the bolt though, and as it didn't need to be so long, just cut off the clogged end!

Then the side-frames and lower foot-plate were joined with 40 thou plastic cross pieces, that are fitted to just clear the ends of the chassis. In the picture above you can just see a plastic "lug" is bonded to the inner face. This fits into the notch in the end of the chassis, it has a chamfered top edge but flat sides and bottom. The chassis is fitted into the frames from above, and with a screwdriver gently prising the cross-members over the ends of the chassis until the lug slots into the notch.

The frame/chassis assembly can then be bolted to the body from below as shown. A valance will need to be added below the body, which will disguise the edge of the plastic lower footplate. From above you can see I added some brass "M" shaped brackets from spare etch, which press on the top of the chassis. Actually the plastic lugs previously mentioned do the locating so these aren't really necessary, but may add some strength. Brass brackets also press against the motor sides to hold the chassis/body vertical.

The frames look OK, axle-boxes line up (reasonably), and ride height matches the drawing, so all good to continue with the build! I've yet to add buffer beams and some details to the under-frames, as well as the valance mentioned, but now I can progress the body too.

I started by opening out a recess above the spring, which gave space to add a few extra leaves from micro-strip, a fiddly job but now they look like they could take the weight of a loco. The W-irons were cut away, and the axle-boxes rounded off slightly, as per an approximation of the drawing. The wagon frame was 1mm shorter than the wheelbase of the chassis so I cut and spliced in a piece of 40 thou, with a splice behind. The notches in the top are cut to clear lugs below the motor. In the photo below one frame is prepared, the other is just started on...

Then on to the outer frames. I'd remembered to take the book to work and photo-copy the drawing at 82%, bringing it to 4mm scale, which makes life easier. I did a few copies while I was at it, allowing me to cut out the frames and stick them to some 20 thou plasticard with a few drops of solvent. It is much easier than all that marking out, a few cuts and I had the basic shaped of the side-frames, there's a mark where the paper was stuck but I'll just stick that on the inside.

Micro-strip was added to the frames according to the drawings and pictures, and the wagon-frames with axle-boxes and springs positioned behind. A dummy lower foot-plate was also cut out, as seen above. The nearest side-frame shows the rear with the wagon sole-bar, this sits just below the motor with notches to clear the plastic motor support brackets on the chassis. The 20 thou frame sits against the side of the motor, which should give the right ride-height. It's now clear why it was useful to have the springs and axle-boxes from one piece of plastic - there is nothing to support them except from the frame above, strictly speaking there should be a gap above the springs too but the lack of that won't be visible!

Holes were then drilled through the plastic lower footplate and the brass footplate of the body for the bolts - I decided one at each end, off-set to allow for couplings to fit centrally. An M2 nut is soldered above the floor, by threading a Vaseline covered bolt with another nut from below and tightening. A little flux applied around the nut with some small pieces of solder, then apply the iron. In theory the Vaseline stops the bolt getting soldered too, and it did - but on the second one some solder got into the bolt thread between the nut and the brass sheet. I managed to unscrew the bolt though, and as it didn't need to be so long, just cut off the clogged end!

Then the side-frames and lower foot-plate were joined with 40 thou plastic cross pieces, that are fitted to just clear the ends of the chassis. In the picture above you can just see a plastic "lug" is bonded to the inner face. This fits into the notch in the end of the chassis, it has a chamfered top edge but flat sides and bottom. The chassis is fitted into the frames from above, and with a screwdriver gently prising the cross-members over the ends of the chassis until the lug slots into the notch.

The frame/chassis assembly can then be bolted to the body from below as shown. A valance will need to be added below the body, which will disguise the edge of the plastic lower footplate. From above you can see I added some brass "M" shaped brackets from spare etch, which press on the top of the chassis. Actually the plastic lugs previously mentioned do the locating so these aren't really necessary, but may add some strength. Brass brackets also press against the motor sides to hold the chassis/body vertical.

The frames look OK, axle-boxes line up (reasonably), and ride height matches the drawing, so all good to continue with the build! I've yet to add buffer beams and some details to the under-frames, as well as the valance mentioned, but now I can progress the body too.

Tuesday, 13 January 2015

Bognor Show

I got over to the Bognor show on Saturday with my Son, who was desperate to spend some pocket money. There was a lot of trade support - though many of the stands were flogging similar stuff so I don't know how they got on, but Joshua found a nice wagon and I picked up some bits and bobs - I do find it hard to pass the Squires stand for one thing!

I was rather taken with this layout by (prolific layout builder) Andrew Knights called "Summer Springs on the New Cut", depicting a small (real) piece of the Norfolk Broads in OO. Despite being a very simple layout it was full of atmosphere and captured the area perfectly.

It even features the Coot Club.

"Lulworth Camp" (Mike Walshaw) also in OO made for a different take on a branch line terminus, with military railway operations adding interest and traffic.

"Selsey Town" (Keith Smith) is of course right up my street. It's not narrow gauge but as a tramway run by Colonel Stephens it had quirky stock and operations. The modelling here is superb - and 7mm scale allows lots of detail, though perhaps compromises the spacious open feel of the prototype. It is also very local to the exhibition venue!

This 7mm NG and SG interchange "Goosemoor Station Stores" (Tom Snook) is based on a real location on the West Somerset Mineral Railway. It's an attractive and interesting model, with some very nice industrial locos in both standard and narrow gauges.

There's a few more photos here. Meanwhile I'm progressing with the Atkinson-Walker loco, so I should have an update shortly.

I was rather taken with this layout by (prolific layout builder) Andrew Knights called "Summer Springs on the New Cut", depicting a small (real) piece of the Norfolk Broads in OO. Despite being a very simple layout it was full of atmosphere and captured the area perfectly.

It even features the Coot Club.

"Lulworth Camp" (Mike Walshaw) also in OO made for a different take on a branch line terminus, with military railway operations adding interest and traffic.

"Selsey Town" (Keith Smith) is of course right up my street. It's not narrow gauge but as a tramway run by Colonel Stephens it had quirky stock and operations. The modelling here is superb - and 7mm scale allows lots of detail, though perhaps compromises the spacious open feel of the prototype. It is also very local to the exhibition venue!

This 7mm NG and SG interchange "Goosemoor Station Stores" (Tom Snook) is based on a real location on the West Somerset Mineral Railway. It's an attractive and interesting model, with some very nice industrial locos in both standard and narrow gauges.

There's a few more photos here. Meanwhile I'm progressing with the Atkinson-Walker loco, so I should have an update shortly.

Thursday, 8 January 2015

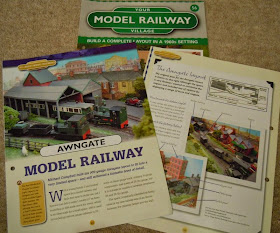

Awngate in a Part-Work

You may remember a couple of years ago one of those part-work magazines starting up, enabling the subscriber to build a model railway step-by-step. Issue one came with a "free" coach for a bargain price - and I admit to picking up a couple for my son's train-set!

Anyway, if you subscribed to Your Model Railway Village and have got as far as issue 56 (by which point I trust the layout is developing nicely) you'll be reading about Awngate! Yes my little 009 layout has made it into print. The publisher has done a very nice job of presenting my short article and photos over a 4-page spread, the text introduces 009 and hopefully shows how a layout can be built in a small space in any home.

And if you've found this blog as a result of the article then welcome!

Anyway, if you subscribed to Your Model Railway Village and have got as far as issue 56 (by which point I trust the layout is developing nicely) you'll be reading about Awngate! Yes my little 009 layout has made it into print. The publisher has done a very nice job of presenting my short article and photos over a 4-page spread, the text introduces 009 and hopefully shows how a layout can be built in a small space in any home.

And if you've found this blog as a result of the article then welcome!

Monday, 5 January 2015

Atkinson Walker Steam Tractor

So here's a project I've already got on the go, albeit progress has been rather slow the last couple of months. I had a Halling chassis and having read the book on the Redlake Tramway, I thought an Atkinson Walker Steam Tractor would be an interesting model. These were vertical-boilered chain-driven locomotives, like the better known Sentinals they used road-vehicle ideas from the time, to make efficient and cheap shunting locomotives. Most were standard gauge but two were built to 3' gauge - the more famous one ended up on the County Donegal Railway in Ireland, where later rebuilt as a Diesel it was named Phoenix. More about that here, where I found this picture of the Redlake loco.

I'd wondered about a scratch-build in plasticard, which shouldn't be too hard apart from the curved corners. I might then have scaled down the body slightly from the 3' gauge versions, however looking at the dimensions I figured that although large, I could just about get away with it in 009. So to make life easier I picked up the Worsley Works scratch-aid kit at EXPO-NG.

As usual for these kits there's some etches for the body - and that's it, no under-frame parts, details, or instructions. The parts are obvious enough though, once I'd figured that the half-etch rebates in the top and bottom of the sides were to go at the outside, and allow beading to be added. So first I cut a hole in the footplate for the chassis to fit, then with the sides carefully curved around and soldered to the footplate and the tank-tops I found some 0.5mm brass wire that fitted into the rebate.

Bending to size, fitting, and soldering the wire was not a little fiddly! Some miniature clothes-pegs (no it isn't a 16mm scale model) from my wife's card-making oddments came in useful.

So the lower body looks OK, though there may be some more cleaning up of excess solder. I've got hand-rails to add in the doorways, then the upper body (windows) and roof to solder on. The roof will restrict access, though the body will be floppy without it, so I need to figure out what's going on below and inside first!

I have added a couple of brackets inside from scrap brass to centre the chassis in place, but I haven't yet figured out how to attach it. I tried making up brass clips to fit into the ends of the chassis, but that's tricky. I also need to make the underframe, which may be narrower than the motor, so I'm thinking of making frames and buffer-beams as a plasticard sub-assembly to which the chassis clips, and can be bolted to the body. Those springs are quite distinctive, any suggestions for suitable mouldings?

I'd wondered about a scratch-build in plasticard, which shouldn't be too hard apart from the curved corners. I might then have scaled down the body slightly from the 3' gauge versions, however looking at the dimensions I figured that although large, I could just about get away with it in 009. So to make life easier I picked up the Worsley Works scratch-aid kit at EXPO-NG.

As usual for these kits there's some etches for the body - and that's it, no under-frame parts, details, or instructions. The parts are obvious enough though, once I'd figured that the half-etch rebates in the top and bottom of the sides were to go at the outside, and allow beading to be added. So first I cut a hole in the footplate for the chassis to fit, then with the sides carefully curved around and soldered to the footplate and the tank-tops I found some 0.5mm brass wire that fitted into the rebate.

Bending to size, fitting, and soldering the wire was not a little fiddly! Some miniature clothes-pegs (no it isn't a 16mm scale model) from my wife's card-making oddments came in useful.

So the lower body looks OK, though there may be some more cleaning up of excess solder. I've got hand-rails to add in the doorways, then the upper body (windows) and roof to solder on. The roof will restrict access, though the body will be floppy without it, so I need to figure out what's going on below and inside first!

I have added a couple of brackets inside from scrap brass to centre the chassis in place, but I haven't yet figured out how to attach it. I tried making up brass clips to fit into the ends of the chassis, but that's tricky. I also need to make the underframe, which may be narrower than the motor, so I'm thinking of making frames and buffer-beams as a plasticard sub-assembly to which the chassis clips, and can be bolted to the body. Those springs are quite distinctive, any suggestions for suitable mouldings?

Saturday, 3 January 2015

Happy New Year!

May I wish all my readers a happy new year, and I hope you had a good Christmas!

I trust Santa brought you some toys. I must have been good, as here's my kit collection to last me a good while yet. The Narrow Planet crew van is an indulgence - like the Baguley Drewry loco kit and several 009 society RNAD wagons I also have waiting to be built - as they are not in period for Awngate. The Chivers coach kit should look at home though so is likely to get built sooner, and I have plans for the Hunslet loco kit that I am keen to crack on with. The KB Scale Ruston LBT will add another loco to my growing O14 fleet - just because I like it! I also got some good railway books to enjoy.

At this time of year it is traditional to review the past year, and look forward to the next. Well to be honest 2014 wasn't a particularly productive year modelling wise. With no central project to focus on I'll admit to getting distracted, and there are some loose ends. That's not a problem - this is just a hobby - and looking at things another way it's been an excellent year. Awngate and Thakeham were out at 3 shows each, two of which were 2-day events, so it has been my busiest year by far on the exhibition circuit. The last few months I have been working on my son's train-set which is both fun and rewarding, if not "serious" in modelling terms.

This year though I have no exhibition bookings to distract me, the club are planning a new layout, which I've been involved with. Planning a club layout is quite different to a personal project so has been interesting in new ways, I expect being involved in building it will be different too. Perhaps it will feature here in due course. "Armchair modelling" has also led to some ideas for future layouts, including a possible replacement for Awngate, though I have no plans to start one in the foreseeable future so don't get excited.

However with the Christmas distractions out the way I do hope to get back to more modelling, there is certainly plenty I'd like to get on with, so you should see a few more productive posts!

I trust Santa brought you some toys. I must have been good, as here's my kit collection to last me a good while yet. The Narrow Planet crew van is an indulgence - like the Baguley Drewry loco kit and several 009 society RNAD wagons I also have waiting to be built - as they are not in period for Awngate. The Chivers coach kit should look at home though so is likely to get built sooner, and I have plans for the Hunslet loco kit that I am keen to crack on with. The KB Scale Ruston LBT will add another loco to my growing O14 fleet - just because I like it! I also got some good railway books to enjoy.

At this time of year it is traditional to review the past year, and look forward to the next. Well to be honest 2014 wasn't a particularly productive year modelling wise. With no central project to focus on I'll admit to getting distracted, and there are some loose ends. That's not a problem - this is just a hobby - and looking at things another way it's been an excellent year. Awngate and Thakeham were out at 3 shows each, two of which were 2-day events, so it has been my busiest year by far on the exhibition circuit. The last few months I have been working on my son's train-set which is both fun and rewarding, if not "serious" in modelling terms.

This year though I have no exhibition bookings to distract me, the club are planning a new layout, which I've been involved with. Planning a club layout is quite different to a personal project so has been interesting in new ways, I expect being involved in building it will be different too. Perhaps it will feature here in due course. "Armchair modelling" has also led to some ideas for future layouts, including a possible replacement for Awngate, though I have no plans to start one in the foreseeable future so don't get excited.

However with the Christmas distractions out the way I do hope to get back to more modelling, there is certainly plenty I'd like to get on with, so you should see a few more productive posts!